三偏心蝶阀介绍

三偏心蝶阀从发明到现在已经有50多年的历史了,在这50多年中,人们也在不断地对三偏心蝶阀进行改良,这也使得三偏心蝶阀的应用领域变得更宽广。原来三偏心蝶阀只用于水介质的截断和联通,三偏心的设计增强蝶阀的功能,已经成为工业工业管道设备中,关键工艺环境最恶劣的条件下性能卓越的阀门之一。

Three eccentric butterfly valve has a history of more than 50 years from the invention to now. In these 50 years, people have also been improving the three eccentric butterfly valves, which makes the application field of three eccentric butterfly valves more extensive. The original three eccentric butterfly valves are only used for the intercept and connection of water medium, and the three eccentric design strengthens the function of the butterfly valve. It has become one of the valves with excellent performance under the worst conditions of the key process environment.

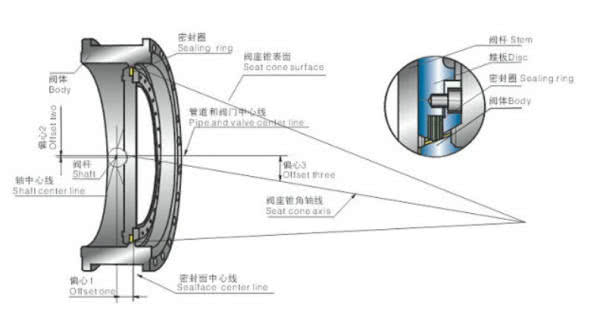

三偏心蝶阀,正如其名称所指,三个独立的偏移被设计成了阀门。具体是指:

1)盘/阀座密封面的中心线,

2)轴相对于孔的中心线的位置;

3)从阀孔的中心线偏移的阀座锥角的轴线。

这三个偏移的组合提供了一个锥形的密封面,最大限度地减少三偏心蝶阀阀座和密封件之间的磨损,提高三偏心蝶阀的使用寿命和密封性。此外,把优阀座面降低到最小,降低三偏心蝶阀的工作转矩。

The three eccentric butterfly valve, as its name implies, three independent offsets are designed to be valves. Specifically, it refers to:

1) the center line of the sealing surface of the disc / seat.

2) the position of the axis of the axis relative to the hole;

3) the axis of the valve seat cone angle deviating from the center line of the valve hole.

The three offset combinations provide a conical seal face to minimize the wear between the three eccentric butterfly valve seats and the seals, and improve the life and sealing of the three eccentric butterfly valve. In addition, reduce the valve seat surface to the minimum and reduce the working torque of the three eccentric butterfly valve.

一般来说,由于三偏心蝶阀密封特性以及成本比其他金属阀座阀门类型选择更有优越性。由于结构紧凑,回转的设计和轻质结构,可以安装和操作方便,他们不需要管支撑。可更换的密封环,允许快速和简单的维修和低扭矩(允许较小的驱动器)意味着更节省成本。

双向零泄漏封闭的金属座只有一次软阀座阀门。这将极大地扩展应用的可能性。灵活的密封环和最佳的扭矩传输,这意味着这些阀门可以提供消防安全设计和密封性能,可以大于一般蝶阀设计的最大温度范围。 传统上,可能会发现在众多行业生成石油和天然气加工、炼油、化工和石化厂、发电、海上平台、供热、造纸、钢米尔斯、糖米尔斯、海水淡化、水处理和分配。他们在所有行业中的使用增加了严格的政府法规和更大的生产需求迫使用户寻求解决方案。用量也节节攀升,已经存在了数十年,特点提供了许多好的解决方案,包括那些具有更大的挑战。这些好处包括运营效率,耐磨料介质和化学品到一定的温度或压力,并在众多的操作条件的多功能性。

Generally speaking, the three eccentric butterfly valve has better sealing performance and cost than other metal seated valve types. Because of its compact structure, the slewing design and lightweight structure are easy to install and operate, and they do not require tube support. The replaceable sealing ring allows for fast and simple maintenance and low torque (allowing smaller drives), which means more cost savings.

Two way zero leakage closed metal seat has only one soft seat valve. This will greatly expand the possibility of application. Flexible seal rings and optimal torque transmission, which means that these valves can provide fire safety design and sealing performance, which can be larger than the maximum temperature range of the general butterfly valve. Traditionally, oil and gas processing, oil refining, chemical and petrochemical plants, power generation, offshore platforms, heating, paper, steel Mills, sugar Mills, seawater desalination, water treatment and distribution may be found in a large number of industries. Their use in all industries has increased stringent government regulations and greater production demand, forcing users to seek solutions. Usage has also been climbing steadily for decades. The characteristics provide many good solutions, including those with greater challenges. These benefits include operational efficiency, wear-resistant materials and chemicals to a certain temperature or pressure, and versatile in many operating conditions.

利用设计的特点,下一代设计提供的功能,进一步提高三偏心蝶阀的安全性和性能,包括:

1、采用精密机加工的密封面和密封环形成金属对金属密封。即使在高温高压以及其他的严苛的服务环境,都可以做到双向密封零泄漏。低摩擦和流线形的标准标准直角圆锥设计,金属对金属能很好的解决热胀冷缩,是在高温高压环境服务的重要特征。金属对金属密封允许应用在有防火要求的油田中。

2、最佳的阀座密封面设计,阀座密封面采用在阀门本体上堆焊司太立硬质合金,使用密封面有更长的寿命和更好的耐磨性,即使反复循环使用。这种密封结构设计减少了和蝶板的摩擦,减少了工作扭矩。

3、特殊的阀座设计使用阀门可以自动调整阀门的密封。浮动的密封环和一个宽的密封环支撑垫片,使用密封性和启闭更加可靠。这种阀座确保阀门有双向密封特性。

4、阀门的设计的定位销在蝶板很低的位置,允许在热膨胀时都有良好的性能,最大程度的减小阀杆的扰度。因此,阀门有很长的使用寿命。

Using the design features, the functions of the next generation design will further improve the safety and performance of the three eccentric butterfly valves.

1, the use of precision machined sealing surface and sealing ring to form metal to metal seal. Even in high temperature and high pressure and other harsh service environment, two-way seal and zero leakage can be achieved. The standard right angle conical design of low friction and streamline shape, metal can solve heat expansion and contraction of metal well, and it is an important feature of high temperature and high pressure environment service. Metal to metal seals are allowed to be used in oil fields with fire protection requirements.

2. The best seat cover design. The seat sealing surface is used to weld the Stellite hard alloy on the valve body. The seal face has longer life and better wear resistance, even if repeated cycle is used. The design of the sealing structure reduces friction with the butterfly plate and reduces the working torque.

3. Special valve seat design uses valve to automatically adjust valve seal. The floating seal ring and a wide sealing ring support gasket are more reliable by using sealing and opening and closing. This seat ensures that the valve has a two-way sealing feature.

4. The location pin of the valve is located at the very low position of the butterfly plate, allowing good thermal expansion performance and minimizing the disturbance of the stem. Therefore, the valve has a long service life.